Ozone Gas Detection for Safety and Disinfection Validation

An Industrial Safety & Process Control Case Study

How we deployed ozone gas detectors to ensure operator safety and validate disinfection effectiveness in a controlled, measurable, and auditable manner.

Safety Risks and Unverified Processes

The customer's ozone-based disinfection system lacked continuous monitoring, creating safety hazards for operators near the generator and leaving disinfection effectiveness unverified. Manual checks were infrequent and provided no historical data for audits.

Key Pain Points

Safety Blindspots: No real-time alerts for hazardous ozone leaks.

Process Guesswork: Lack of data to confirm if disinfection was successful.

Compliance Gaps: No auditable records of safety or process parameters.

The Brains of the Smart System

At the heart of our gas detection solution is a powerful IoT development board. This system integrates calibrated electrochemical sensors with an edge controller, processes data locally, and ensures secure, reliable communication with the cloud for real-time monitoring, alerts, and historical data logging.

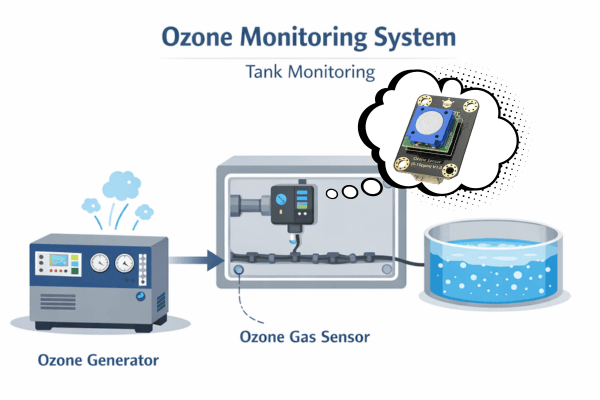

A Distributed IoT-Based Ozone Monitoring System

We implemented a distributed ozone gas detection solution using calibrated sensors integrated with a central IoT monitoring platform for real-time visibility and control.

Multi-Point Detection

Sensors were placed at the generator (safety), contact tank (effectiveness), and outlet (residual check) for full system visibility.

IoT System Architecture

Electrochemical sensors fed data to an edge controller, which securely transmitted it to a cloud platform for dashboards, alerts, and reporting.

Safety & Compliance

Thresholds based on occupational exposure limits triggered instant audio/visual alarms and mobile notifications to ensure rapid response.

Enhanced Safety and Data-Driven Validation

Enhanced

Operator safety with continuous ambient ozone monitoring.

Validated

Disinfection effectiveness with data-driven performance metrics.

Improved

System reliability and faster troubleshooting through trend analysis.

By combining ozone gas detectors with an IoT monitoring platform, the customer transformed a reactive operation into a controlled, data-backed process, ensuring both personnel safety and process integrity.